UNIQUE AND ESSENTIAL DEVICE

LARGE LOAD

New regulations and sterilisation concepts have improved the sterilisation process in all medical and dental facilities; this has led to a wider range of instruments, a spread of professional facilities, and consequently the need for autoclaves with large load capabilities.

The Onyx project aims to satisfy these needs with new, specific solutions which can also manage partial loads easily.

ENERGY SAVING

Onyx B has low energetic consumption as well as unbeatable consumption/load ratio.

Economic saving and benefit for the environment.

DOUBLE LOAD... SAME TIME

The standard size autoclave sterilises about 4 kg of instruments, while Onyx B can sterilise about 8 kg.

With 1 double load there is 50% time saving.

BEST INSTRUMENT MANAGEMENT

The large load autoclave rationalises instrument flow, so increasing operative efficiency.

Efficiency means profit, another advantage of Onyx B.

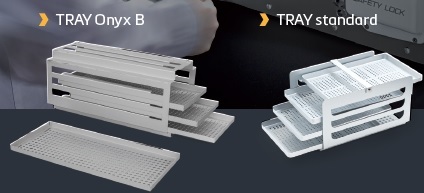

LONGER TRAYS (+30%)

Wide trays enable instrument insertion in large envelopes, allowing for rational load placement for large load sterilisation according to the correct guidelines for load placement.

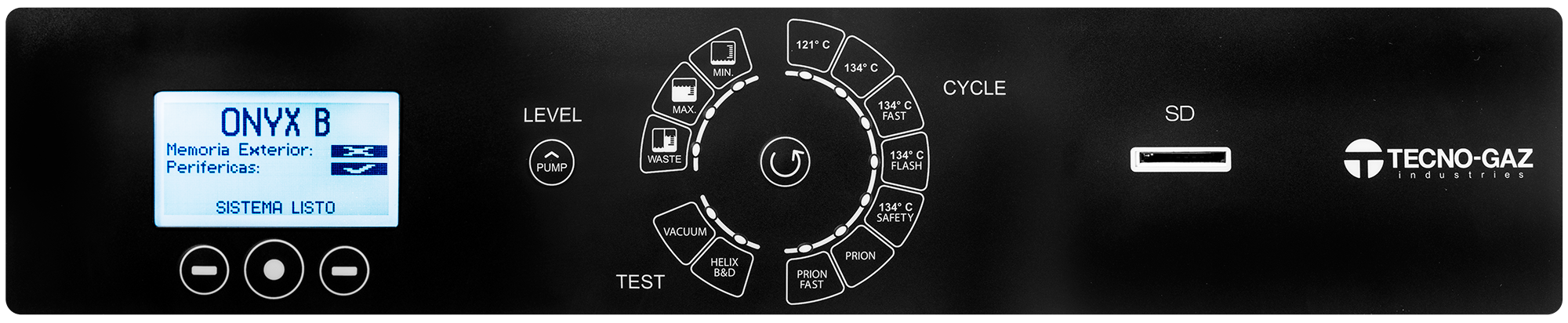

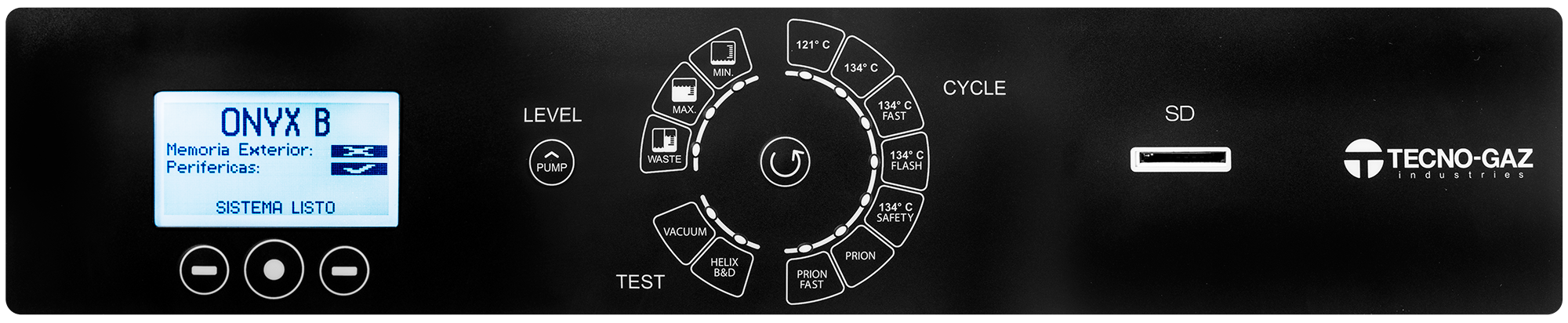

SD CARD

The SD CARD system ensures recording and storage of all cycles which can then be downloaded on your PC for their management.

The SD CARD system allows constant machine updating by simple data download, then insertion into the autoclave system.

An extraordinary option in order to have a constantly efficient and updated device.

FL (FULL LOAD) SYSTEM

To avoid manual loads with the possibility of water overflow, the automatic clean water tank system of Onyx B has a level sensor control pump with automatic lock.

Front loading, no opening cover or removal system, enabling simple machine positioning.

PURA PLUS

The autoclave is autonomous, equipped with a double tank for clean water and waste water. It is ready for connection to the water supply through the PURA Plus osmosis system.

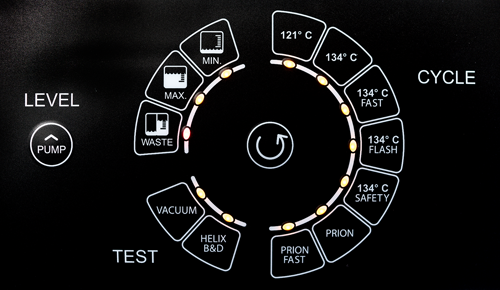

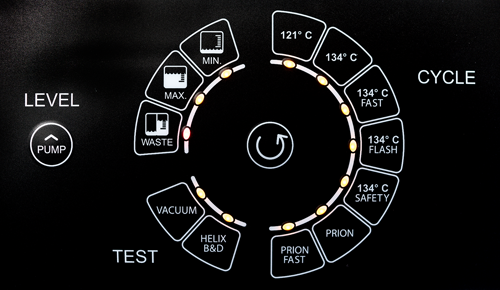

7 STERILISATION CYCLES

Onyx B was designed to rationalise the work of sterilisation operators, therefore the autoclave is equipped with cycles which have been expressly conceived to improve time management and operator’s requirements in outpatient clinics.

COMPLETELY AUTOMATIC CYCLES

All cycles are completely automatic and all phases are managed by the advanced card equipped with a powerful microprocessor.

Each phase (vacuum, preheating, exposure time, drying) is monitored, backed up and managed automatically.

There is no human intervention in cycle operation.

ID SYSTEM

Operator's authentication integrated system protected by password, permitting, at the end of the cycle, association of the operator to the sterilised load with visual operator identification.

The same authentication is also reported by the load traceability procedure.