Smart Trolley Evo. The evolution of daily efficiency with the new line of professional furnishings for dentistry. Even more efficient. Even... smarter.

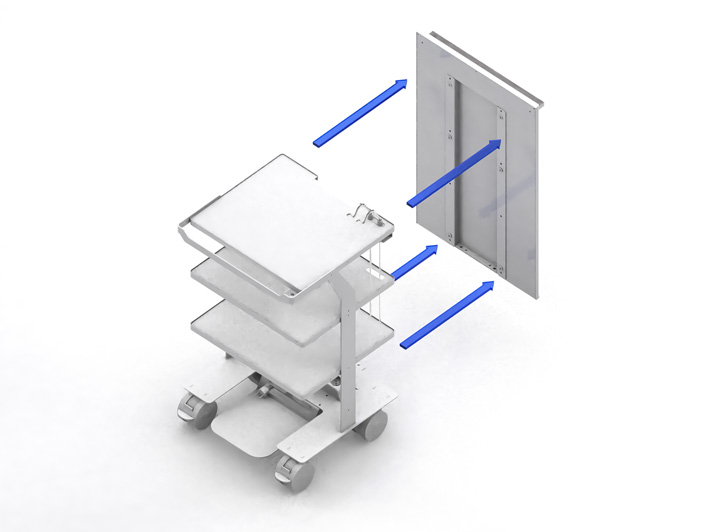

The Smart Trolleys project was created to make work easy and productive. The logical step was to transform furnishings perceived as simple containers, into out and out 100% operational devices. The big advantage is the "adaptability" of the trolleys, to the advantage of the dentist’s operativity, who can thus move as he pleases choosing the most suitable devices for his needs and configuring them as desired.

All this finds its place in the Intraoperative Smart Trolley which, when closed, conceals everything inside, and when in the operating set-up, i.e. pulled out of its box, becomes an indispensable instrument.

The Smart Trolley Intra model is enriched with a 4-drawer version, with a retractable and rotating tray arm, which allows tools and consumables to be brought closer to the treatment area on the assistant's side, which can be used during surgery surgery or dental treatment, avoiding unnecessary travel and saving time.

The solution is the Electromedical Smart Trolley with its own centralised power supply system, modular nature and ability to accommodate bulky control pedals, becomes an indispensable functional and organisational hub.

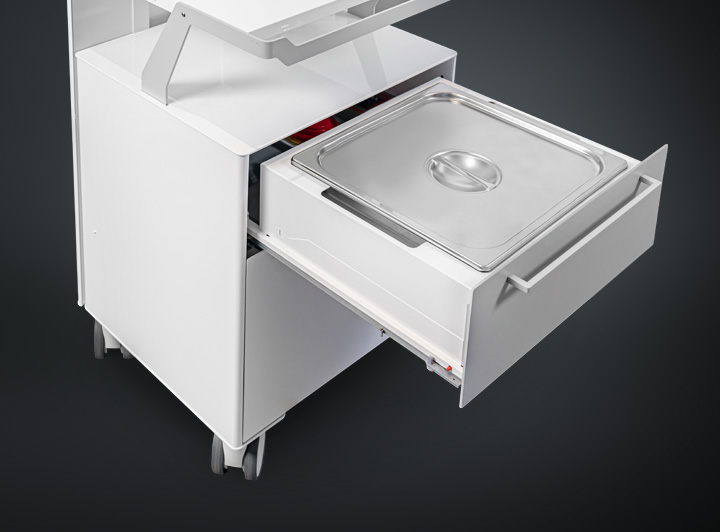

Post-operative Smart Trolley, thanks to its built-in decontamination tank and the collection compartments is the hub for collecting and sorting of infected material.

Productivity and efficiency come from optimising the many ‘simple gestures’ repeated many times a day. With the sink-dispenser unit, the dental team efficiently integrates the SmartTrolley Evo furnishing system and can count on: easy access to disposable materials and their replenishment when depleted; easy access to the waste disposal compartment with "knee" opening; high quality of mixer, materials and construction standards to reduce maintenance and simplify sanitisation.

Download product brochure

Smooth sliding and Soft Close mechanism (cushioned final stop to closing of the drawer). Guides are tested in continuous use by means of opening and closing cycles with a frequency of 7 cycles per minute. This test guarantees the functionality of the guides for 60,000 cycles equal to a continuous use of more than 20 years.

Smooth-running swivel castors with parking brake. Mounted on ball bearings with a load bearing capacity of 100 kg, thanks to their large diameter (100 mm) they are able to overcome obstacles such as: grouting, joining areas between different floors, small obstacles.

The paint finish, the final element of a high quality production process, is carried out with antibacterial epoxy powders. The epoxy powder coating is tested and certified with rigorous resistance tests (scratch and accidental falling objects) to guarantee integrity of use. In addition, the high quality of the paints used prevents discolouration caused by UV radiation. This coating protects the structure from aggressive substances and prevents surface discolouration.